When it comes to injection molding, it is actually a very widely used process. But, the important point which is being considered while transfer the new injection molder tool is planning and having communication with the new injection molder by clearly mentioning the project aim. At the beginning of the process, it is important to mention the frequency of the updates and project time lines.

For the new injection molder, it is important to give the all relevant information about the tools which defining the proper evaluation and inspection of tools. The furthermost the relevant discussion which includes the molder part information, mold specifications, drawings quality information and post molding information.

To transfer the injection mold tool, it is not important to be stressful or to take any burden for the transferring of tool and also it is not important to be worried about the cost of the transfer of the injection mold tool because it is very cheap process and there are some others parameters which is important for the transfer of injection mold tool which will discuss in the following.

Contents

What are the benefits of an injection molding tool transfer?

There are some benefits of an injection molding tool transfer. Basically, the injection molding tool transfer is the significant manufacturing skills because in some places it is important to do this step for the efficient output. To confirm the corporation is a good match for the both consumers, the quality necessities are assessed.

For the both consumers and buyer, it is very beneficial to tool for injection molding which might be further use to complete the desired work/process. One of the best benefits of the injection molding tool transfer is, it might make a chance to re-align the abilities and necessities. This is very difficult step to re align the abilities and necessities but by the injection molding tool transfer, it becomes the easiest way to do this. It is an opportunity for the intermediary to fill or complete a detailed results of the condition of molding process to transfer the injection molding tool.

What are the cons of an injection molding tool transfer?

In most of the conditions it is very challenging to get efficient and detailed tooling records for past assets with this injection molding tool transfer. But nowadays it is very easy to get the results from the tooling records because of the digital period of time.

The one of the cons of the injection molding tool transfer is to obtained the desired work with more accurate results because for the new molding it is new part to work with it. For the more efficient work it might take a time to take place the oldest tool and work with more efficiently.

What are some best practices for injection molding tool transfers?

There are five best practices which is being implement for the injection molding tool transfer. These all practices carry equal importance to the contribution of injection molding tool transfer.

- Then the second practice for the injection molding tool transfer is to propose a sensible or reasonable time barrier, if conceivable, to confirm satisfactory source all over the transfer, estimation, alteration, and re-requirement shares of the method.

- Then the second practice for the injection molding tool transfer is to explain and share all the reasons for the transfer which is being important for the injection molding tool transfer.

- Then the third practice for the injection molding tool transfer is to develop a transfer checklist which confirm us to provide or accept current statistics. From this it is also noted that the list could be extensive but it must have the part drawings, 3D drawing files, previous shots, dimensional history or explanation, quality scales, maintenance background, quality background, drawing of the tooling and any auxiliary or robot necessities etc.

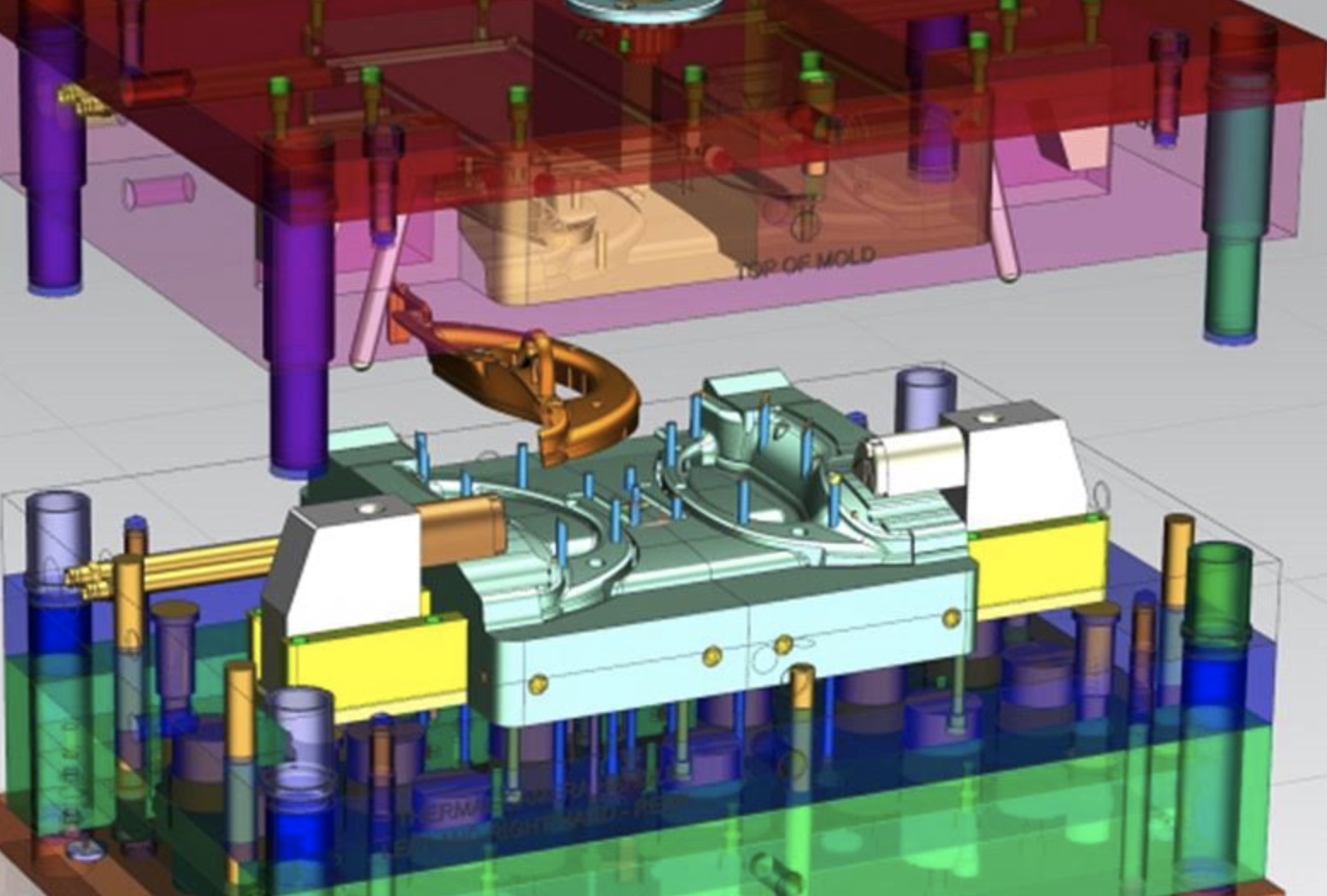

- Then the fourth practice for the injection molding tool transfer is to allow the new injection molder at minimum a week to deportment their own tooling assessment, and to exchange fittings, couplings, and connectors to get-up their observes. As per a sample of PCI’s team every so often desires time to way networks in the ejector plates for the wiring of pressure sensor.

- Then the 5th practice for the injection molding tool transfer is to complete or ample a complete dimensional plan next the transfer. This is a favorable time to re-measure plastic module circumstances and dimensional outcomes.

For the more practices of the injection molding tool transfer our team will be assured for the account manager, account engineer, program promotion manager, tooling and quality legislatures. For the best practices of the injection molding tool transfer our team should fabricated of an account manager, account engineer, program launch manager, tooling and quality legislatures.

This team is in control for all surfaces of the overthrow procedure from timeline management, tool analysis and charge to selection and PPAP offer. They are there to professionally change your transfer lists through the method in a timely way.

What are the phases of an injection mold tool transfer process?

There are six best phases which is being implement for the injection molding tool transfer. All these phases carry equal importance to the contribution of injection molding tool transfer.

- The 1st phase of the injection molding tool transfer is Partnership: which is the Main to the achievement of the project in launching and keeping well-defined announcement networks.

- The 2nd phase of the injection molding tool transfer is Assessment: All through this time, the teams do works with the client to completely recognize the creation purposes from instruction access to consignment.

- The 3rd phase of the injection molding tool transfer is Schedule: which is Created on the on-location valuation, a transference of timetable that will be industrialized.

- The 4th phase of the injection molding tool transfer is Safety stock: In which six weeks is a distinctive time edge for security of ordinary allocation.

- The 5th phase of the injection molding tool transfer is Validation: The main aim of authentication is to get client endorsement on individually portion that will be formed in the original injection molding capability.

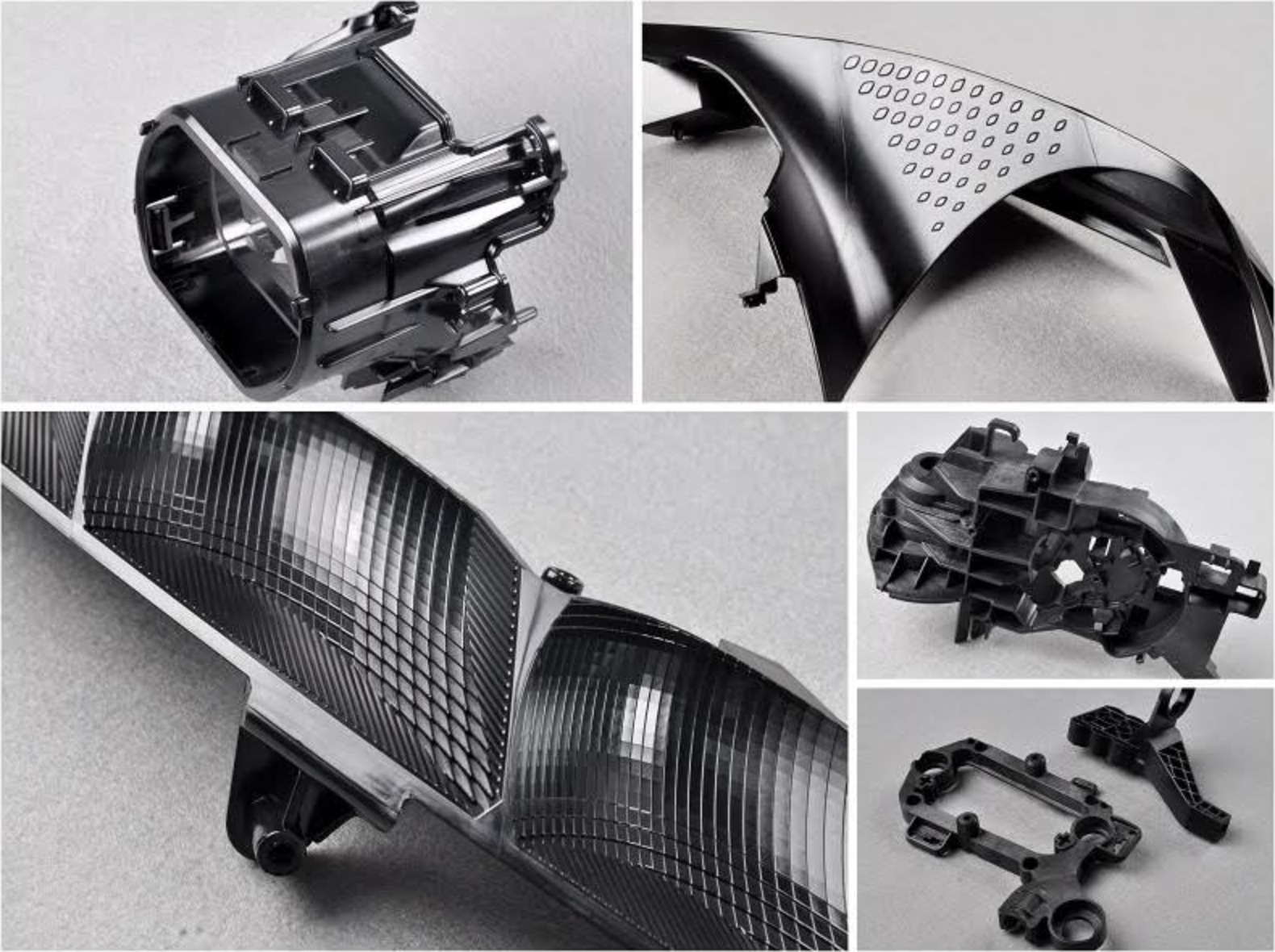

- The 6th phase of the injection molding tool transfer is Production molding: When part authentication is done, the new injection molder’s creation team will start to foodstuffs the plastic machineries.

These all the phases of the polymer injection molding tool transfer are important and perilous that predominantly the authentication stage. The occupied with a knowledgeable injection molding team that procedures the newest technology and advanced manufacturing methods will alleviate related risks and become your chunk to the manufacture molding stage quicker. At work with a team that have the complexity in their practical upbringings will be an essential advantage to the obligation and asset complete to the transfer method.

Conclusion:

The original injection molder ought to accomplish Circuses for you with the purpose of estimate and support of its recital. Already your manufacture rounds start, be certain to confirm that all shares obey to your conditions. They must have the aptitude to provide the strategy of experimentation, whole method authentication, recital competences lessons, FMEA and tradition regulator procedures built on your scheme necessities, to preserve manufacturability of our portions, the original molder should assess, the ailment of the mold, the resin choice, the portion geometry and the value of stipulations.